You want your gas wood chipper to work well and be safe. Start with clear steps for fixing wood chipper problems. Always keep yourself safe and work in a safe place before you fix anything. Some common problems are blunt blades, bad ejection, and engine not starting. Use this guide to help you fix things yourself and make good repairs.

-

Bad chip quality can happen from blunt blades or wrong blade distance.

-

Poor ejection can come from old drive belts, weak engine power, or blocked ejector wings.

-

Engine may not start because of fuel problems or broken spark plugs.

Key Takeaways

-

Always put safety first. Wear protective gear. Get your work area ready before you use the gas wood chipper.

-

Check your chipper often. Look at the blades, spark plugs, and fuel. This helps it work well and stops it from breaking down.

-

Fix problems like dull blades and blockages quickly. This stops more damage and helps the chipper work better.

Safety Precautions

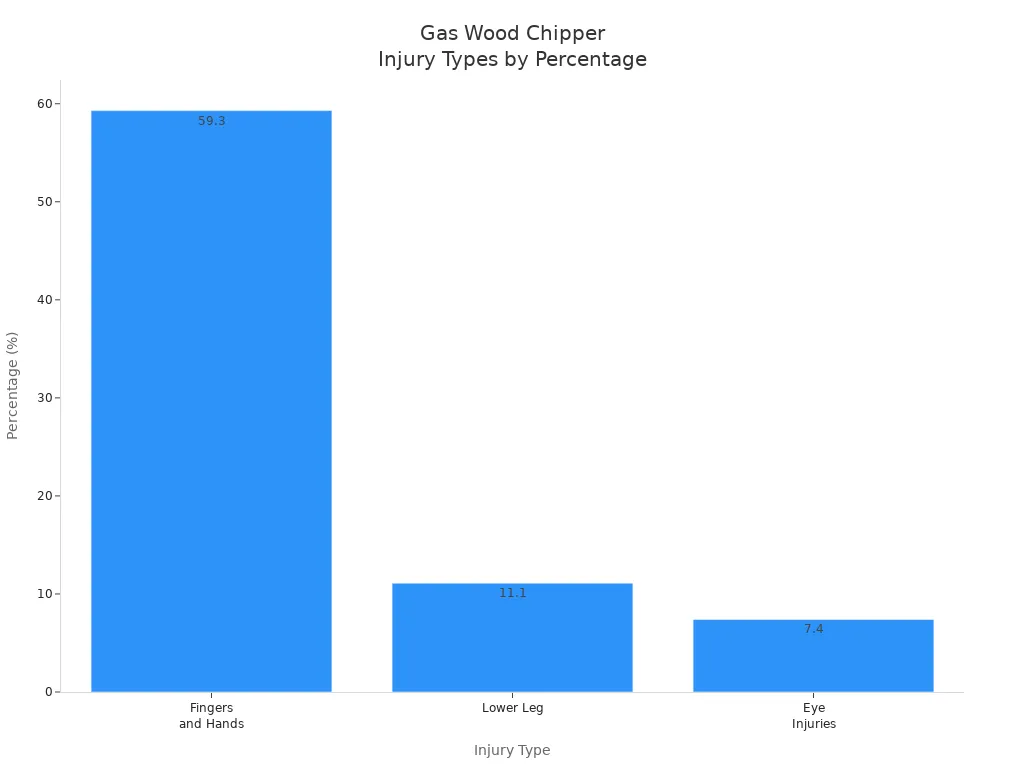

Safety is very important before you fix your gas wood chipper. Many people get hurt every year. Some injuries are very serious. Look at the table below to see how often these injuries happen:

|

Injury Type |

Percentage (%) |

Description |

|---|---|---|

|

Fingers and Hands |

59.3 |

Most injuries need hospital care. Some people lose fingers or break bones. |

|

Lower Leg |

11.1 |

Legs can get crushed or broken if caught in rollers. |

|

Eye Injuries |

7.4 |

Branches and twigs can hit eyes. This can cause bad eye injuries. |

|

Nonfatal Injuries (Total) |

~1200-1300 |

Every year, many people go to hospital because of wood chippers. |

|

Tree Workers Injured |

~200 |

Tree workers get hurt by chippers each year. |

|

Hospital Admissions |

~120 |

About 120 people go to hospital. Most are around 50 years old. |

|

Age Range of Injured |

2 to 83 |

People of all ages can get hurt, even young children. |

Personal Protection

-

Always wear the right safety gear.

-

Use safety goggles to keep your eyes safe.

-

Put on strong gloves to protect your hands.

-

Wear steel-toe boots and long trousers for your legs.

-

Ear defenders help stop loud noise from hurting your ears.

-

A helmet keeps your head safe.

Safe Setup

-

Get your work area ready before you start.

-

Make sure the ground is flat and dry.

-

Take away anything you could trip over.

-

Lock the chipper wheels so it stays still.

-

Keep children and pets far away.

-

Only use dry wood with no stones or metal.

-

Work outside where air moves well.

-

Do not refuel near fire or flames.

-

Check that the chute is clear.

Power Off

-

Turn off the chipper before you look or fix anything.

-

Take out the spark plug so it cannot start by accident.

-

Wait until all moving parts have stopped.

-

These steps help you stay safe.

-

Always put safety first when using strong machines.

Gas Wood Chipper Inspection

Before you start any repairs, you should inspect your gas wood chipper carefully. This first step helps you spot simple problems and avoid bigger issues later.

Visual Checks

Look at your machine closely. Check for loose bolts, cracked parts, or missing screws. Make sure the chute is clear and nothing blocks the blades. If you see oil leaks or fuel stains, clean them up and find the source. Worn or damaged parts can cause the chipper to work poorly or even break down.

Fuel and Oil

Your gas wood chipper needs the right fuel and oil to run well. Always use fresh petrol and check the oil level before each use. Old fuel can make the engine hard to start.

Never use fuel with ethanol, as it can damage the engine. Fill the oil to the correct level, but do not overfill.

System Basics

You should check a few basic things before deeper troubleshooting:

-

Make sure the machine has enough petrol.

-

Inspect the blades and anvil for damage or wear.

-

Check the engine oil level.

-

Review the user manual for your model.

Tip: Regular checks help your gas wood chipper last longer and work better.

Engine Troubleshooting

When your gas wood chipper refuses to start or keeps stalling, you need to look at the engine closely. Many engine issues can stop you from working or cause consistent stalling. You can fix most problems with simple checks and solutions.

No-Start Issues

You may face no-start problems when the engine does not start or shows difficulty in starting. These common symptoms often point to a few main causes. Use this ordered list to guide your wood chipper troubleshooting:

-

Spark Plug – Inspect for wear or damage. Replace if you see cracks or heavy dirt.

-

Carburettor – Old fuel can clog the carburettor. Clean or replace it if you find blockages.

-

Ignition Coil – Test the coil for proper function. Replace if it fails.

-

Flywheel Key – Look for breakage. Replace if broken.

-

Recoil Starter – Make sure it engages well. Replace if it does not work.

You may notice the small engine hard to start or the small engine stops after a few seconds. These symptoms often mean you need to check the parts above. If you see small engine leaks gas, you should fix leaks before starting again. Engine failures often come from ignoring these checks.

Tip: Always use fresh petrol and check for leaks before starting. Old fuel leads to starting problems and stalling.

Spark Plug & Air Filter

Dirty spark plugs and clogged air filters cause engine issues and stalling. You need to inspect these parts often. The table below shows the steps you should follow:

|

Diagnostic Step |

Action |

|---|---|

|

Check air filter |

Inspect for dirt. Clean or replace if needed. Follow the Engine Owner's Manual. |

|

Check spark plug(s) |

Look for dirt or cracks. Replace if damaged. Clean oily plugs before reinserting. |

If you ignore these checks, you may face no-start problems or consistent stalling. Clean air filters help the engine breathe. Good spark plugs make starting easier. You avoid engine failures and keep your gas wood chipper running well.

Note: Replace spark plugs and air filters every season for best results.

Throttle & Carburettor

Throttle and carburettor problems often cause stalling and poor performance. If the throttle sticks or the carburettor clogs, you may see the engine does not start or stalls after a few seconds. You should check the throttle cable for smooth movement. Clean the carburettor with approved cleaner. If you find old fuel, drain and refill with fresh petrol.

You may notice difficulty in starting or the engine stops after a few seconds. These are common symptoms of throttle or carburettor faults. If you see small engine leaks gas, inspect the carburettor seals and fuel lines. Replace damaged parts to prevent further problems.

Solutions for stalling include cleaning the carburettor, adjusting the throttle, and replacing worn parts. Regular troubleshooting helps you avoid engine issues and keeps your wood chipper working safely.

Dull Blades

Blade sharpness is very important for good feed and chipping. Dull blades cause feed issues and make the chipper work harder. You may see the machine struggle to process branches or leave rough chips. Regular wear and tear from usage makes blades dull over time. If you feed hard wood or hit foreign objects, the blades lose their edge faster. The type of material you feed also affects blade life.

-

Blades become dull from regular use.

-

Contact with stones or metal in the feed damages the blades.

-

Feeding tough or knotty wood wears blades quickly.

If you notice poor feed or rough chips, check the blades for nicks or dull edges. Sharpen or replace them as needed. Always inspect the blades before each use to avoid feed issues and keep your chipper working well.

Note: Never feed branches with nails, stones, or metal. These objects damage the blades and cause common wood chipper problems.

Blockages

Blockages are one of the most common problems you may face with an wood chipper. When you feed too much material or use green branches with leaves, the chute can clog. You might see the blades stop spinning or the engine stall. Blockages often happen when you do not clear the chute or feed material too quickly.

To clear blockages, follow these steps:

-

Turn off the engine and disconnect the spark plug before you inspect the machine.

-

Look for obstructions in the blades and chute. Remove any stuck material by hand or with a tool.

-

If you chip green branches, remove the screens to help prevent clogging.

-

Check that the blades spin freely after clearing the blockage.

-

If the engine floods, separate it from the shredder and diagnose the issue.

⚠️ Always put safety first when troubleshooting feed problems. Never reach into the chute while the engine runs.

Blockages slow down your work and can damage the chipper. Regular cleaning and careful feeding help you avoid these common wood chipper problems. If you keep having feed issues, check the user manual for more wood chipper troubleshooting tips.

Wood Chipper Troubleshooting for Noises

Unusual Sounds

You may hear strange noises when you use your gas wood chipper. These sounds often warn you about problems inside the machine. Listen for rattling, grinding, or banging. These noises can mean loose or broken parts, dull knives, or misaligned components. If you notice any unusual sounds, switch off the chipper straight away. Do not ignore these warnings. You should check for a dull or damaged knife and sharpen or replace it if needed. Make sure the knife sits properly on the flywheel. Adjust it if you see it is out of place.

Tip: Always stop the machine and inspect it if you hear abnormal noises. Ask an expert to repair it if you cannot find the cause.

Vibrations

Vibration is another sign that something is wrong with your chipper. You may feel the machine shake more than usual. This can happen if you process hardwoods, large or oddly shaped branches, or run the chipper at high speed. Poor design or weak construction also increases vibration. If you notice strong vibrations, clean the chipper and repair or replace any damaged parts. High vibration can damage the machine and make it unsafe.

-

Hardwoods and oversized pieces cause more vibration.

-

Well-built chippers have less vibration.

-

Fast operating speeds increase shaking.

Loose Parts

Loose parts often cause both noise and vibration. You should check all bolts, screws, and fittings before each use. Tighten anything that feels loose. If you find broken or missing parts, replace them. Regular checks help you avoid bigger problems and keep your chipper safe.

Note: Regular wood chipper troubleshooting helps you spot loose parts early and prevent accidents.

Wood Chipper Maintenance

Routine Checks

You keep your gas wood chipper running smoothly by following regular wood chipper maintenance. Start each session by inspecting safety guards and shields. Make sure they are not damaged. Clean the feeding chute and discharge area after every use. This prevents clogs and helps you spot problems early. Check blade sharpness before you begin. Sharpen or replace blades if needed. Change the oil after the first eight hours, then every fifty hours. Inspect spark plugs every ten to twenty hours. Clean or replace the air filter at the end of each season. Lubricate moving parts and tighten fasteners. Adjust belt tension if you notice slack.

|

Maintenance Task |

Recommended Interval |

|---|---|

|

Change oil |

After first 8 hours, then every 50 hours |

|

Check blade sharpness |

Before each use, sharpen every 25 to 50 hours |

Blade & Belt Care

You extend the life of your chipper by caring for blades and belts. Inspect blades daily for dullness, chips, or cracks. Sharpen blades every 25–50 hours, or sooner if you see uneven chips or slower performance. Clean blades and the surrounding area after each use. Check belt tension and look for wear. Replace belts if you see cracks or fraying.

Tip: If your chipper uses more fuel or works slowly, sharpen the blades and check the belts.

Preventative Tips

You avoid costly repairs with good wood chipper maintenance habits. Check for loose bolts and damaged parts before each use. Sharpen blades every 10–20 hours for best results. Clean air filters and inspect spark plugs often. Store your chipper in a dry place. Use rust-prevention products during seasonal care. Add fuel stabiliser if you plan to store the chipper for more than 30 days.

If you notice overheating, excessive smoke, grinding noises, or the flywheel stalls, seek professional help. These signs mean you need expert wood chipper troubleshooting.

You make your gas wood chipper safe by doing regular checks. These checks also help it work well.

|

What You Should Do |

|

|---|---|

|

Engine won’t start |

Put in new fuel, look at spark plug |

|

Unusual noise |

Stop the chipper, check blades and tighten them |

-

Sharpen the blades often, clean the filters, and look at safety guards.

-

Follow this guide to keep your chipper working better for longer.

FAQ

Why does my wood chipper keep stalling?

You may have a clogged air filter or old fuel. Clean the filter and use fresh petrol. Check the spark plug for damage.

How often should you sharpen chipper blades?

You should sharpen blades every 25–50 hours of use. Inspect them before each session. Dull blades reduce performance and can damage your machine.

What should you do if the chipper makes loud noises?

-

Stop the machine immediately.

-

Inspect blades and fasteners for looseness.

-

Tighten or replace any damaged parts before restarting.