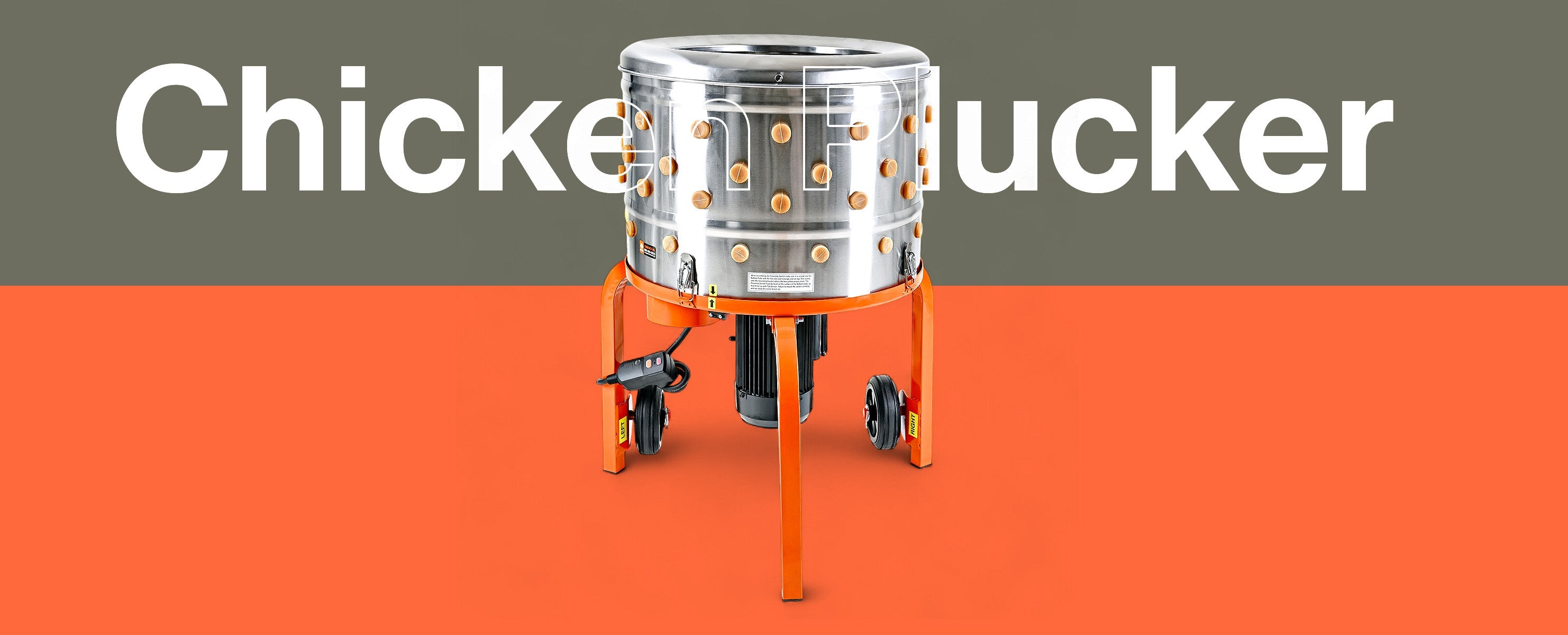

You must pick the best Chicken Plucker for your poultry jobs. Taking feathers off poultry needs quick work and good results. Think about how much you need to process, how much space you have, if it fits with your setup, how much power it uses, its design, what it is made of, and how much it costs. Getting a Chicken Plucker helps you work faster, do more, and makes these machines very important for your poultry work.

Key Takeaways

-

Pick the correct size of chicken plucker for your flock. A small plucker works well for backyard birds. Bigger flocks need larger machines for better results.

-

Think about which type of plucker is best for you. Drum pluckers are good for small groups of chickens. Tub pluckers can clean more chickens faster.

-

Make sure your scalder and plucker sizes match. This helps everything run smoothly. It stops delays and keeps your work moving.

Plucker Size & Processing Volume

Batch Size & Flock Needs

You need to think about how many birds you want to process at one time. The size of your flock will help you choose the right plucker. If you keep a small flock, you may not need a large machine. Many backyard poultry keepers have flocks of 10 to 50 birds. Small commercial operations often work with more birds in each batch.

-

Backyard poultry: 10–50 birds

-

Small commercial poultry: More than 50 birds

If you process only a few birds at a time, a smaller plucker will work well. You can finish your work quickly and save space. If you have a larger flock, you will need a bigger machine. This will help you keep up with your poultry processing needs. You will also see better productivity and less waiting time.

Tip: Always match the size of your plucker to your usual batch size. This will help you get the best efficiency from your machines.

Drum vs. Tub Chicken Plucker

You will find two main types of defeathering machines: drum pluckers and tub pluckers. Each type works best for different flock sizes and needs.

A drum plucker uses a rotating drum with rubber fingers. You place the bird inside, and the machine removes the feathers as the drum spins. Drum pluckers suit small batches and backyard poultry keepers. They are easy to use and do not take up much space.

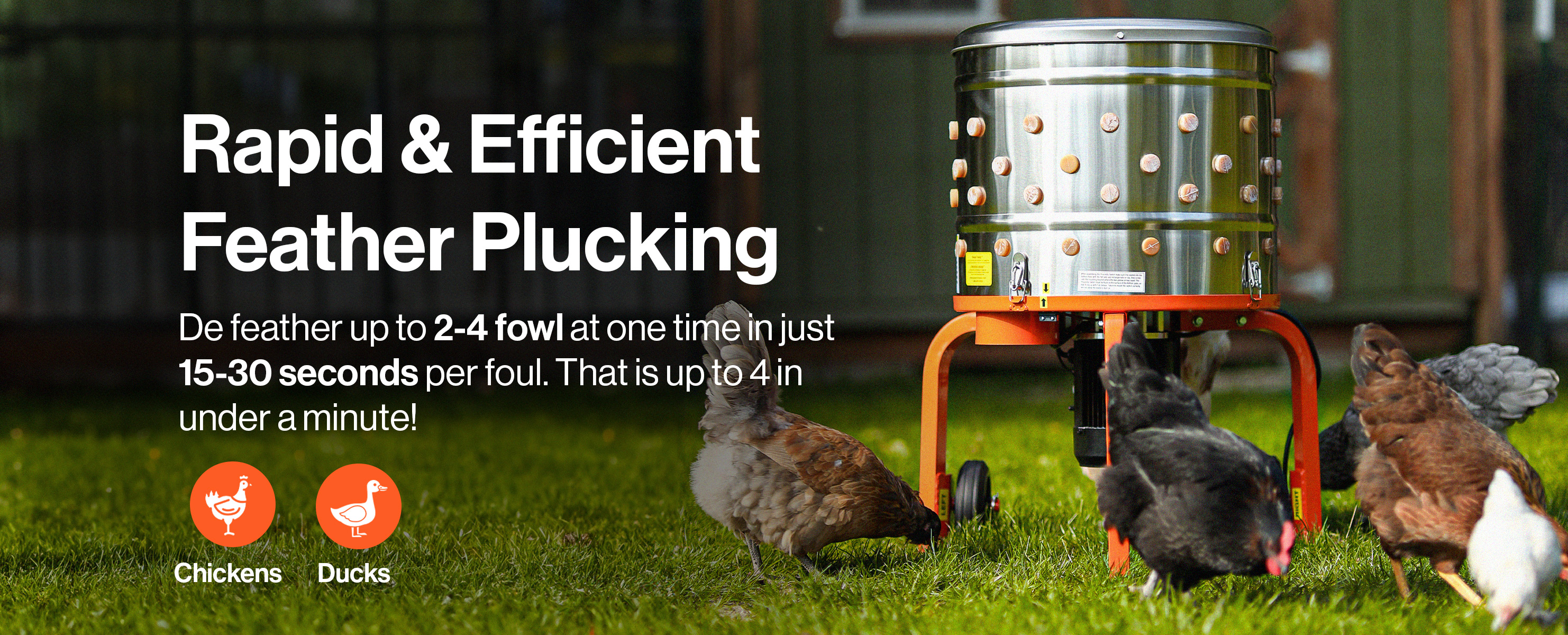

A tub plucker has a larger tub with spinning plates and many rubber fingers. You can process several birds at once. Tub pluckers work well for small commercial operations or anyone with a bigger flock. These machines offer faster defeathering and higher productivity.

|

Type of Plucker |

Best For |

Batch Size |

Space Needed |

Defeathering Speed |

|---|---|---|---|---|

|

Drum |

Backyard poultry |

1–3 birds |

Small |

Moderate |

|

Tub |

Small commercial flocks |

4+ birds |

Larger |

Fast |

You should compare both types before you buy. Drum pluckers are simple and good for beginners. Tub pluckers handle more birds and save time if you have many to process. Both machines help you with defeathering, but the right choice depends on your flock and your space.

Note: Choosing the right size and type of plucker will make your poultry processing smoother and more efficient. You will spend less time on defeathering and more time on other important tasks.

Space & Equipment Compatibility

Matching Scalder and Plucker Capacity

It is important to match your scalder and plucker sizes. If your scalder is small but your plucker is big, you might work slower. If your scalder is big but your plucker is small, birds will wait for defeathering. The right match keeps your work steady and smooth.

Here is a simple guide for picking your machines:

|

Processing Capacity |

Scalder Size |

Plucker Size |

|---|---|---|

|

2 to 4 chickens |

Manual scalder |

23" plucker |

|

4 to 6 chickens |

30" rotary scalder |

27" plucker |

|

10+ chickens |

41" rotary scalder |

35" Turkey plucker |

When you have more chickens, you need bigger machines. This table helps you pick the right size for your flock. It also helps your defeathering go well.

Compact vs. Stationary Plucker Models

You should think about how much space you have for your machines. Compact plucker models fit in small spaces. You can move them and store them easily. These are good for backyard poultry keepers or people with little space.

Stationary plucker models need more room. They are best for bigger poultry jobs. These machines are stronger and work faster, but they must stay in one place. If you process lots of birds, a stationary model saves time and effort.

Tip: Always check your workspace size before buying new machines. This helps you avoid problems and keeps your poultry area safe and tidy.

Power & Electrical Requirements

Electric vs. Manual Plucker Options

You need to choose between electric and manual pluckers. Electric pluckers have motors that spin rubber fingers. This makes removing feathers much quicker. Manual pluckers need you to turn a handle or use a drill. These take more time and effort. Electric pluckers are good for bigger batches. They help you save energy. Manual pluckers are better for small flocks. They are simple tools for easy jobs.

Here is a table to show the differences:

|

Feature |

Electric Pluckers |

Manual Plucking |

|---|---|---|

|

Processing Speed |

Much faster, can do many birds in minutes |

Slower, takes a long time for lots of birds |

|

Labour Intensity |

Needs little physical effort |

Needs lots of effort, can be tiring |

|

Productivity |

Makes work quicker and easier |

Depends on how fast you work |

Electric pluckers help you do more work with less effort. Manual pluckers need more strength and are best for small jobs.

Voltage and Setup Considerations

You should check the power needs before buying electric pluckers. Most small chicken pluckers use a 800 W motor. They run on 220 V single-phase voltage.

Always match your scalder and plucker to your power supply. This keeps your work safe and smooth. Check the plug and wiring before you set up your machines. Good planning stops problems and helps your poultry area work well.

Tip: Ask an electrician to check your power before you install new machines. This helps you avoid electrical problems and keeps your poultry work safe.

Design, Material & Durability

Plastic vs. Metal Chicken Plucker

When picking a chicken plucker, you need to choose between plastic and metal. Plastic pluckers are light, so you can move them easily. They are good for small poultry jobs and cost less money. Metal pluckers, especially ones made from stainless steel, last longer and do not rust. Metal machines work better for a long time and are stronger. The table below shows why stainless steel is a good choice for defathering machines:

|

Material |

Properties |

Impact on Longevity |

|---|---|---|

|

Stainless Steel |

Strong and does not rust |

Makes the machine last longer |

|

Stainless Steel |

Hard to damage or wear out |

Helps the machine stay strong |

|

Stainless Steel |

Very tough and reliable |

Lets the plucker work for years |

Cleaning and Maintenance Needs

You need to clean your plucker every time you use it. Use water to wash away feathers and dirt from all parts. Defeathering machines do not have many parts, so looking after them is easy. You should check the picker sticks and the main motor often. Follow these steps to keep your machine working well:

-

Wash the machine well after each use to stop feathers and germs building up.

-

Clean with mild soap and warm water.

-

Dry every part before you put it away.

Looking after your machine keeps it working well and helps you remove feathers easily.

Safety Features

You should check for safety features when buying defathering machines. Guards cover moving parts to keep your hands safe. Emergency stop buttons help you stop the machine quickly if needed. Good machines have these features to protect you while you work. Always look for clear instructions and warning signs on your plucker. A well-designed machine helps you stay safe and makes feather removal easier.

Budget & Cost-Effective Choices

Drill Attachment Plucker for Beginners

If you are new to poultry work, you might want a simple tool. A drill attachment plucker is cheap and easy to use. You connect it to a normal power drill. Hold the bird and let the rubber fingers spin. The feathers come off as the fingers move. You do not need a big machine or lots of space. Many beginners pick this tool because it costs less and works for small jobs.

A drill attachment plucker helps you learn how to remove feathers. You can process one or two birds at a time. You do not have to buy expensive machines. This choice is good for backyard poultry keepers who want to try before buying bigger equipment.

Tip: Check the drill attachment before you buy it. Strong rubber fingers and tough parts help the tool last longer.

Here is a table to help you choose:

|

Feature |

Drill Attachment Plucker |

Standard Defeathering Machine |

|---|---|---|

|

Cost |

Low |

Medium to High |

|

Space Needed |

Very little |

More |

|

Batch Size |

1–2 birds |

4+ birds |

|

Learning Curve |

Easy |

Moderate |

|

Maintenance |

Simple |

More involved |

You can use a drill attachment plucker for small poultry jobs. You save money and space. You also learn how to remove feathers without spending much.

Long-Term Value of Advanced Defeathering Machines

If you want to process more birds, you may need a better machine. Advanced defeathering machines work faster and give better results. These machines have strong motors and tough parts. You can process many birds quickly. The quality of your poultry stays the same each time.

Buying advanced machines is a good investment for the future. These machines last longer and break less often. You spend less time fixing them. They also have safety features and are easy to clean. Many commercial poultry keepers use advanced machines because they save time and effort.

Note: Look for machines made from stainless steel. Stainless steel does not rust or break easily. Your equipment will work well for many years.

Here are some reasons to buy advanced machines:

-

You process bigger batches of poultry.

-

You want faster feather removal and better results.

-

You need strong machines for regular use.

-

You want high quality and easy cleaning.

The table below shows the benefits of advanced machines:

|

Benefit |

Description |

|---|---|

|

Durability |

Strong materials last for many years |

|

Efficiency |

Fast processing saves time |

|

Safety |

Guards and emergency stops protect you |

|

Quality |

Consistent results for every batch |

|

Maintenance |

Easy cleaning and fewer repairs |

Think about your needs before you buy a new machine. If you process poultry often, advanced machines are worth the money. You spend less time removing feathers and get better results. You also make your poultry area safer and more organised.

Tip: Compare different machines and read reviews. Good research helps you find the best machine for your budget and needs.

Choosing a Defeathering Machine: Practical Tips

Comparing Types and Capacities

It is important to look at different defeathering machines before buying. Each machine type works best for certain poultry setups. Drum pluckers are good for small batches. Tub pluckers are better for bigger groups. You should check how many birds each machine can handle. Some machines can only process a few birds at a time. Others can do many birds together. You also need to think about the speed and size of the machine. Fast machines help you finish your work quickly. Big machines need more room. Small machines are easy to fit in small spaces.

Tip: Always make sure your scalder and plucker match in size. This helps your work go smoothly and stops delays.

Here are some simple tips for people buying for the first time:

-

Make sure your scalder and plucker match in size.

-

Pick a scalder that fits how many birds you process.

-

Check what power the machine needs.

-

Look at how the machine is designed.

-

Think about how much money you want to spend.

Matching Plucker to Workflow

You need to pick a chicken plucker that fits your daily work. If you process a few birds at a time, a small machine is best. If you have lots of birds, you need a stronger machine. These machines work faster and give better results. You should think about how often you use the machine. If you use it a lot, you need one that lasts longer. Machines that are easy to clean help keep your area neat. Safety features help protect you while you work. Good machines make your poultry better and save you time.

Note: Always look at the design and what the machine is made of. Stainless steel machines last longer and keep your poultry work safe.

A plucker that fits your needs makes feather removal easier. You get good results every time and your work goes faster. Your poultry processing becomes more organised and efficient.

There are lots of options when picking a chicken plucker. You should think about how many birds you have. Make sure you have enough space for the machine. Think about how much money you want to spend. Look at different defeathering machines and compare them. Pick a plucker that works well with how you do your jobs. Good machines help you remove feathers better. Choose a defeathering machine that suits your poultry needs. Make sure your machine works well with your setup for long-term use.

FAQ

How do you clean a chicken plucker after use?

You should rinse the machine with warm water. Remove feathers and dirt. Dry all parts before storing. Regular cleaning keeps your equipment safe and working well.

Can you use a chicken plucker for other poultry?

You can use the machine for ducks and turkeys. Check the size and settings before starting. Some models work better for larger birds.

What safety tips should you follow when using a chicken plucker?

You must keep hands away from moving parts. Wear gloves for protection. Always read the instructions before starting. Switch off the machine before cleaning.