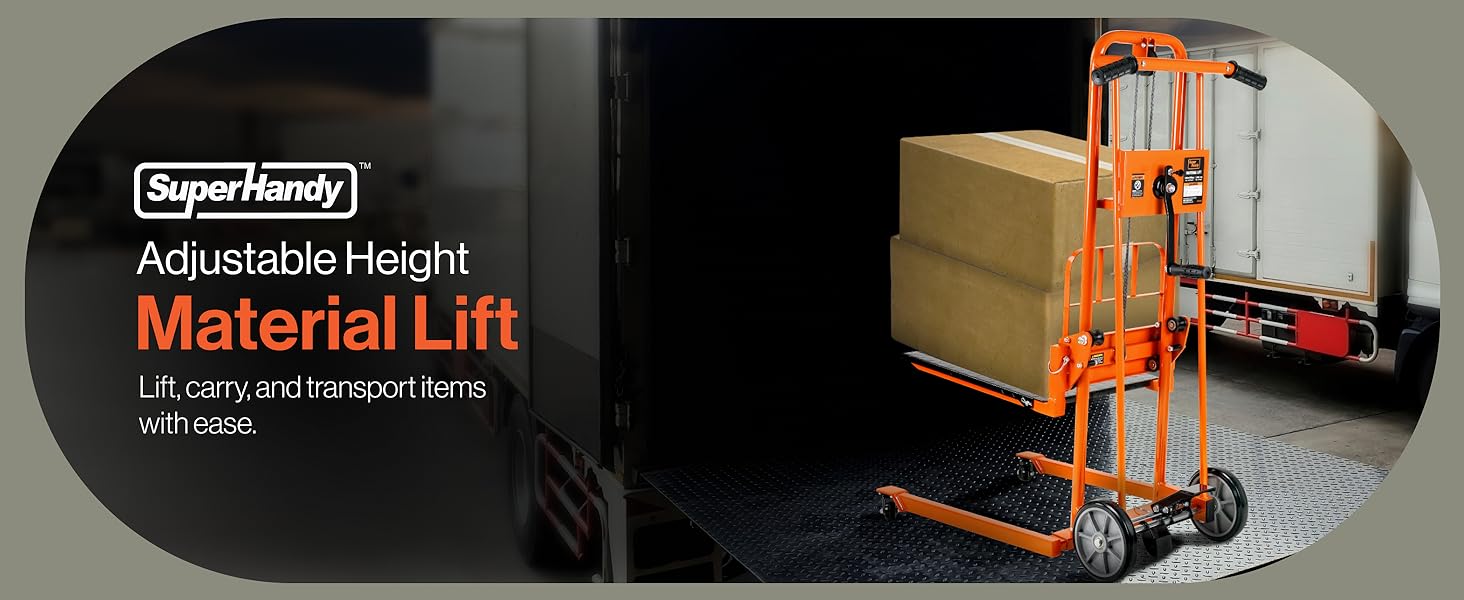

You use a material lift winch stacker to move heavy things easily. This stacker mixes mechanical lifting with a small size. You use it to lift things up and move them sideways. In small spaces like workshops, stacker machines like winch operated pallet stacker machines help you lift things safely and save space.

Key Takeaways

-

A material lift winch stacker lets you lift heavy things easily. It is good for small places like workshops. - Always look at the stacker's frame and hoist for damage before you use it. This helps keep you safe when lifting things. - Using a stacker saves time and energy. It is better than lifting by hand. You can finish your work faster.

Material Lift Winch Stacker Components

Winch and Lifting Mechanism

You find the winch at the heart of every stacker machine. This part lets you raise and lower heavy items with ease. The winch uses pulleys and steel cables to help you control the lifting process. You turn the handle, and the hoist lifts the load smoothly. The manual winch gives you direct control, so you can stop or start the lifting whenever you want. You use the hoist to move loads up or down, making the stacker safe and efficient. The winch mechanism makes lifting equipment simple for anyone to use.

-

The winch mechanism uses pulleys and cables for vertical lifting.

-

You control the hoist directly, so you can lift or lower loads safely.

-

The stacker machines let you handle heavy items without much effort.

Mast and Frame Construction

You see the mast and frame as the backbone of the stacker. Most stacker machines use Q235 carbon steel for strength and durability. The mast supports the hoist and keeps the machine stable during lifting. The frame holds everything together and protects the stacker from damage. You rely on the sturdy construction to keep the stacker safe while you work.

Tip: Always check the frame for signs of wear before using the stacker machine.

Forks, Platform, and Wheels

You use the forks or platform to hold the load. The wheels let you move the stacker horizontally across the floor. You can adjust the fork width on some stacker machines to fit different items. The wheels make it easy to transport heavy loads after lifting them with the hoist.

Here is a table showing typical load capacities for stacker machines:

|

Capacity (kg) |

Max. Lift Height (mm) |

Fork Width Adjustment (mm) |

Weight (kg) |

|---|---|---|---|

|

250 |

1560 |

150-690 |

140 |

|

500 |

1560 |

150-690 |

146 |

|

1000 |

1560 |

Fixed |

182 |

You choose the right stacker based on the weight you need to lift and move. The stacker machines help you handle loads safely and quickly.

How the Stacker Works

Lifting and Lowering Loads

You operate the stacker by turning the winch handle. The hoist lifts the load upwards. The steel cables and pulleys inside the machine help you raise items smoothly. You control the lifting process with your hands. You can stop the hoist at any height. This gives you full control over lifting operations. You use the stacker machines to lift boxes, crates, or other heavy items. The mast keeps the machine stable while you work. You lower the load by slowly releasing the winch. The hoist brings the item down gently. You avoid sudden drops, which keeps lifting equipment safe. You always check the load before lifting. You make sure the weight does not exceed the stacker’s capacity.

Note: You should never stand under a raised load. This keeps you safe during lifting operations.

Moving Materials Horizontally

You move the stacker across the floor using its wheels. The machine glides easily on smooth surfaces. You push or pull the stacker to the desired location. The forks or platform hold the load securely. You can adjust the fork width on some stacker machines. This helps you fit different items. You use the hoist to keep the load steady while moving. You avoid bumps and obstacles to protect the machine and the load. You use the stacker to transport heavy loads from one area to another. You save time and effort compared to manual lifting.

Here is a simple table showing steps for moving materials:

|

Step |

Action |

Purpose |

|---|---|---|

|

1 |

Secure the load |

Prevent shifting |

|

2 |

Check wheel path |

Avoid obstacles |

|

3 |

Push or pull machine |

Move load horizontally |

|

4 |

Lower load with hoist |

Prepare for unloading |

Safety Features

You find several safety features on stacker machines. The frame uses strong steel to prevent bending. The mast supports the hoist and keeps the machine upright. You see brakes on the wheels. These help you stop the stacker when needed. You use the winch to control the lifting speed. This prevents accidents during lifting operations. You check the safety labels on the machine before use. You follow the instructions for safe lifting. You wear gloves and safety shoes to protect yourself. You inspect the hoist and cables for damage. You report any problems before using the stacker.

Tip: You should always read the safety manual for your stacker. This helps you avoid injuries and keeps the machine in good condition.

Stacker Applications and Benefits

Workplace Uses

A stacker helps in many workplaces. People use stacker machines in warehouses, factories, and shops. Workers use the stacker to move boxes and supplies. You can lift things onto shelves or move them across the floor. A stacker is good for small spaces where big machines do not fit. You see stacker machines in storage rooms with little space. The hoist lifts goods, and the wheels help you move them. The machine helps you organise stock and keep your area neat.

Efficiency and Safety

A stacker makes work faster and easier. You save time and energy instead of lifting by hand. Mini winch stackers can lift up to 120Kg in narrow halls. You can load a metre of items or lift things up to a metre high. Stacker machines help you work quickly and well. The hoist lets you control lifting and keeps you safe from harm. The strong frame and mast keep the stacker steady. You use the brakes to stop the machine when you need to. You pick a lifting tool that keeps you and your team safe.

Tip: Always check the lifting equipment before you use it to stay safe.

Ease of Operation

A stacker is easy to use. Some features make your job simpler:

-

The machine is light and small, so you can move it easily.

-

Reversible forks give more height in tight places.

-

The automatic brake keeps you safe and makes things easier.

-

Out-riggers help the stacker stay steady when lifting.

You move the stacker without much effort. The hoist lifts and lowers loads smoothly. You can store the stacker easily when you are not using it. You choose a lifting tool that suits your needs and helps you work well.

You use a material lift winch stacker to lift and move things easily. The stacker is strong and small. Each part helps you do your job better:

|

Feature |

Description |

|---|---|

|

Capacity Range |

Can lift up to 227kg |

|

Working Heights |

Can reach up to 4.2m |

|

Versatile Design |

Good for shipping, lifting, and installing |

|

Customisable Options |

Base and boom can be changed for crane jobs |

|

Compact Design |

Simple to move and store |

|

Flexible Operation |

Forks and winch handle can be switched around |

You get safety and speed from the stacker:

-

It moves well and has brakes to keep it still

-

It meets EN1757-1:2001 safety rules

-

The winch is made for safe and easy lifting

The mast is very strong and lifts things safely every time. You keep your work area safe and tidy with a material lift winch stacker.

FAQ

What is the difference between a material lift winch stacker and manual hydraulic stacker machines?

A material lift winch stacker lifts things using a winch. Manual hydraulic stacker machines use hydraulic pumps to lift loads.

Can you use a manual chain hoist with a stacker?

You can use a manual chain hoist for lifting jobs. But you must make sure it fits your stacker before you use it.

How do you maintain a stacker for safe operation?

You look at the cables, wheels, and frame often. You clean the moving parts and check for any damage before each use.

Tip: Always follow the maker’s maintenance guide for the best results.